Media Perspective | The Innovation "Wind" of Ningbo Snow Dragon is in Full Swing

"An old steed in the stable still aspires to gallop a thousand miles." As he envisions the path forward for the company, 74-year-old He Cailin's eyes shine with hope. The year 2020 was extraordinary for He Cailin and Xuelong Group: the company successfully went public on the Shanghai Stock Exchange; with the implementation of the "National VI" emission standards, the engine cooling fan system they launched has continuously expanded its market capacity due to its advantage of reducing vehicle fuel consumption by 6%.

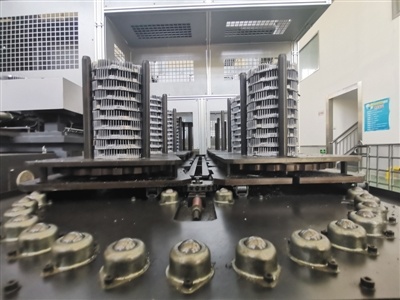

The clutch fan assembly blank produced by Xuelong Group, photo by Hong Hengfei.

Approaching the "Invisible Champion"

"An old horse in the stable aspires to gallop a thousand miles." Envisioning the company's path forward, 74-year-old He Cailin's eyes shine.

The year 2020 was extraordinary for He Cailin and Xuelong Group: the company successfully went public on the Shanghai Stock Exchange; with the implementation of the "National VI" emission standards, its engine cooling fan system, which reduces vehicle fuel consumption by 6%, has seen a continuously expanding market.

After a 24-year journey, Ningbo Xuelong Group Co., Ltd. has developed from a nearly bankrupt township fan factory to having over 200 customers, with its engine cooling fan assembly products holding the largest market share in the domestic market. He Cailin, a former elementary school teacher with five entrepreneurial experiences, has never stopped innovating in business.

"In March, during the resumption of work and production, General Secretary Xi Jinping visited Beilun, Zhejiang for inspection, which greatly inspired us." He Cailin told the Science and Technology Daily reporter that through several iterations of products and adherence to national brands, the company was recognized as a "hidden champion" by the Zhejiang Provincial Economic and Information Commission in 2017 and is striving to become a "national-level manufacturing single champion."

Using all his strength to embark on a difficult fifth entrepreneurial journey.

In 1981, He Cailin borrowed 1,300 yuan from friends and relatives to start a school-run paper and rubber factory. After more than a year, at the age of 35, he achieved a profit of 16,000 yuan in one year.

This made him somewhat well-known locally, and his business acumen was further recognized by local officials, leading him to manage three enterprises in succession. This young man from Ningbo, who had dropped out of school due to poverty, completed the transformation from teacher to entrepreneur.

In 1996, a large number of auto parts mold enterprises emerged in Beilun, Zhejiang, but the now fifty-year-old He Cailin had to face a "hot potato"—the Beilun Automotive Plastic Fan Factory, a township enterprise in Xiapu Town, was in dire straits with three consecutive years of losses, two changes of factory manager, and a debt of 1.95 million yuan. It urgently needed a new manager to turn the situation around. That same year, He Cailin's electrical distribution factory, which he had managed for 12 years, had an annual sales of 1.6 million yuan, which was enough for him to live comfortably for the rest of his life.

"At that time, the fan factory was losing 50,000 yuan a month, and we were so poor that we couldn't make ends meet. The town leaders approached me many times, and many workers wanted to work to support their families. I thought, this factory is not beyond saving." Driven by the spirit of entrepreneurship, He Cailin decided to take over the old factory and analyzed that the main reason for the losses was poor management, not a lack of technology.

"Factory Manager He mobilized the entire factory to find ways to squeeze out big profits from small places." A senior employee recalled that originally, the fan was manufactured with iron plates processed by external factories, with a processing fee of 25 cents per piece, and the waste material also belonged to the external factory. After learning this, he invested 96,000 yuan to purchase a 160T old punch press, bringing all the iron plate business back in-house, reducing the processing fee to a few cents per piece, and keeping the waste material for the factory.

It was this meticulous approach, along with methods such as using goods to offset debts and actively communicating with customers to stabilize the market, that allowed He Cailin to achieve a profit of 130,000 yuan in the first year, marking the beginning of Xuelong Group.

Setting a "big goal" to support the brand with research and development.

In He Cailin's mind, the small victory in the first year was not enough to create a significant impact.

At that time, the main fans used in domestic commercial vehicles were imported nylon fans and domestic metal fans. This newly revived small enterprise added pressure on itself and set a "big goal" to achieve the localization of nylon fans.

"The performance of the product ultimately lies in the hands of the customers." He Cailin said that after successfully developing the first modified nylon fan in the country, they offered this batch of new products for free trial installation at several automotive and engine factories, allowing users to compare performance and durability with imported fans and domestic metal fans.

This bold experiment quickly spread the company's reputation in the industry, gaining recognition from various automotive and engine manufacturers, and becoming a supporting supplier. By engaging in industry-university-research cooperation, Xuelong Group successfully mastered the patent technology for modifying nylon materials, and the self-made nylon fans were priced at only one-third of imported products, achieving a product layout of "using plastic instead of steel."

In 2005, Xuelong Group's generator cooling fan sales ranked fourth globally and first domestically, attracting the attention of a foreign investment holding company. The other party hoped to buy the Xuelong brand at a price several times higher than the market price, but after a month, they could not sway He Cailin's thoughts.

"The domestic auto parts industry is not advantageous, we hope to build a good national brand and lead in high-tech enterprises, opening up cooperation in a better posture." He Cailin said that the company also established the first laboratory in the domestic industry to test fan product performance, gradually evolving from a single research and development and manufacturing of automotive plastic cooling fan products to a supply capability that is series-based, assembly-based, and integrated for major engine manufacturers.

"From the initial professional manufacturers in Taiwan to later well-known universities such as South China University of Technology and Zhejiang University, thanks to industry-university-research cooperation, Xuelong's research and development network is expanding." He Cailin stated that the company achieved an operating income of 365 million yuan in 2019, investing no less than 4% of sales revenue as research and development funds each year. In the past three years, more than 200 independent research and development and synchronous research projects have been completed, forming a pattern of producing one generation, reserving one generation, and researching one generation.

"Zhejiang has listed the automotive industry as a key cultivated world-class advanced manufacturing industry cluster. We will seize this opportunity to consolidate our leading position in the industry, expand the new energy vehicle market, and make the Chinese Xuelong brand more well-known worldwide." He Cailin said.

No content!